1. Introduction to SMT

Surface Mount Technology (SMT) is an important process in PCB (Printed Circuit Board) manufacturing, where electronic components are mounted directly onto the surface of the printed circuit board. SMT has become the most popular method for assembling electronic components, gradually replacing traditional through-hole technology.

2. Steps in the SMT processing process

The SMT processing process includes many different steps, each step requires precision and strict quality control:

a. Solder Paste Printing

This process begins with printing solder paste onto the solder points on the surface of the PCB. Solder paste, a mixture of solder powder and flux, is printed through a stencil to ensure that only the necessary locations have solder paste.

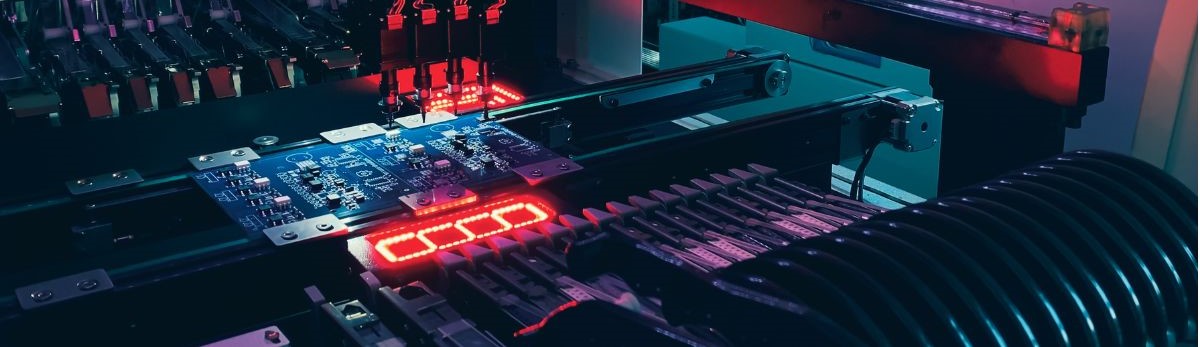

b. Component Placement

After printing the solder paste, the SMD (Surface Mount Device) components are placed onto the PCB surface using an automatic component placement machine. This machine is capable of placing components with high speed and accuracy.

c. Reflow Soldering

After the components are placed in the correct position, the circuit board will be passed through the reflow oven. During this process, the temperature will be gradually increased to melt the solder paste, bonding the components to the circuit board. The circuit board will then be cooled to fix the solder connections.

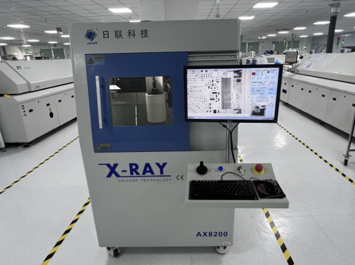

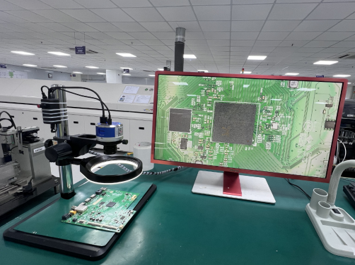

d. Inspection and Quality Control

The final step in the SMT process is quality inspection. Common inspection techniques include Automated Optical Inspection (AOI) and X-ray inspection. AOI helps detect defects such as missing components, misplaced components, or soldering errors. X-ray inspection is often used to inspect solder connections underneath BGA (Ball Grid Array) components.

3. Benefits of SMT technology

-

- Increased component density: SMT allows smaller and closer components to be mounted, increasing component density on the circuit board and reducing product size.

- High automation: SMT processes are easily automated, increasing productivity and reducing manufacturing costs.

- Higher electronic performance: SMT solder connections have higher mechanical strength and better electrical conductivity.

SMT technology plays an important role in improving the efficiency and quality of PCBA manufacturing processes. Thanks to SMT, modern electronic products can be manufactured with smaller sizes, higher performance and lower costs.

Image of SMT production line

Some equipment display

|

|

|

|

| Moisture proof cabinet | X-RAY | Feeder Calibrator | Electron microscopy |

|

|

|

|

| LCR Tester | ESD Tester | Furnace temperature tester | Solder paste mixer |

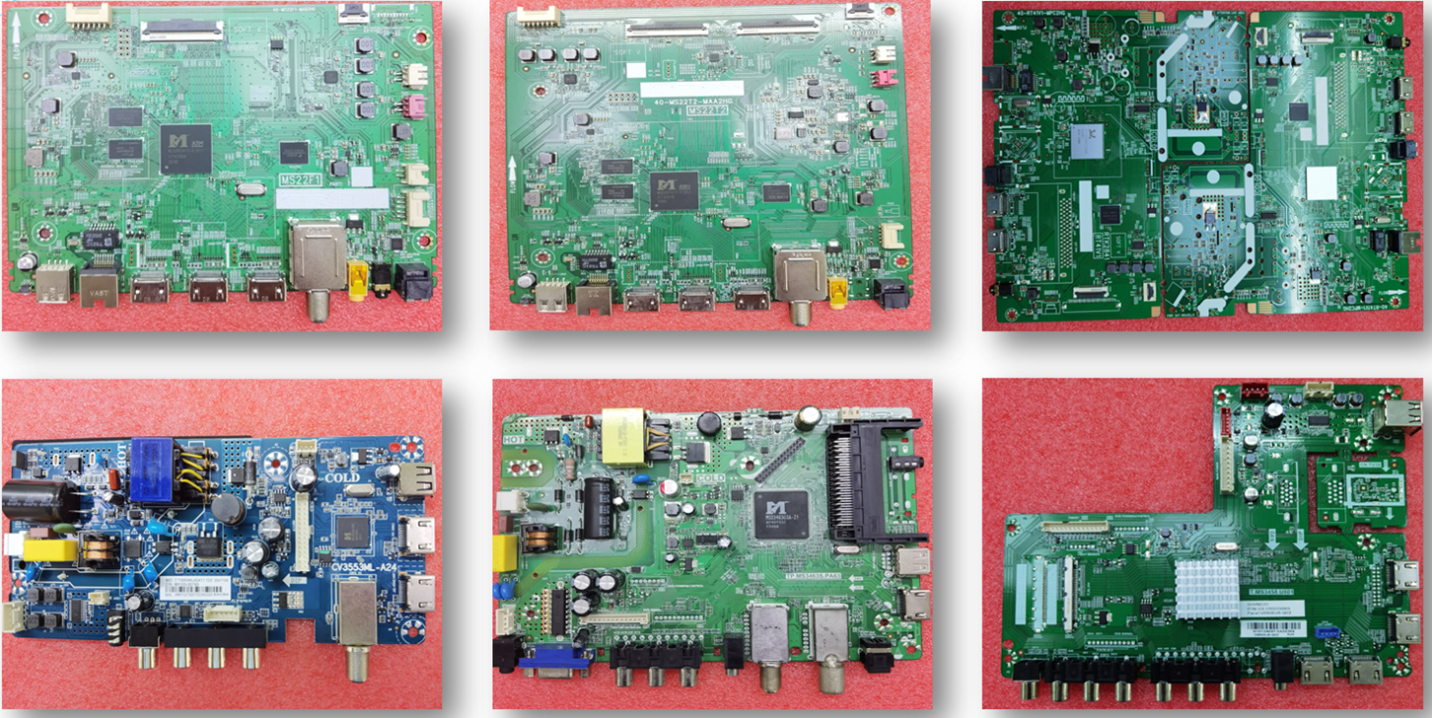

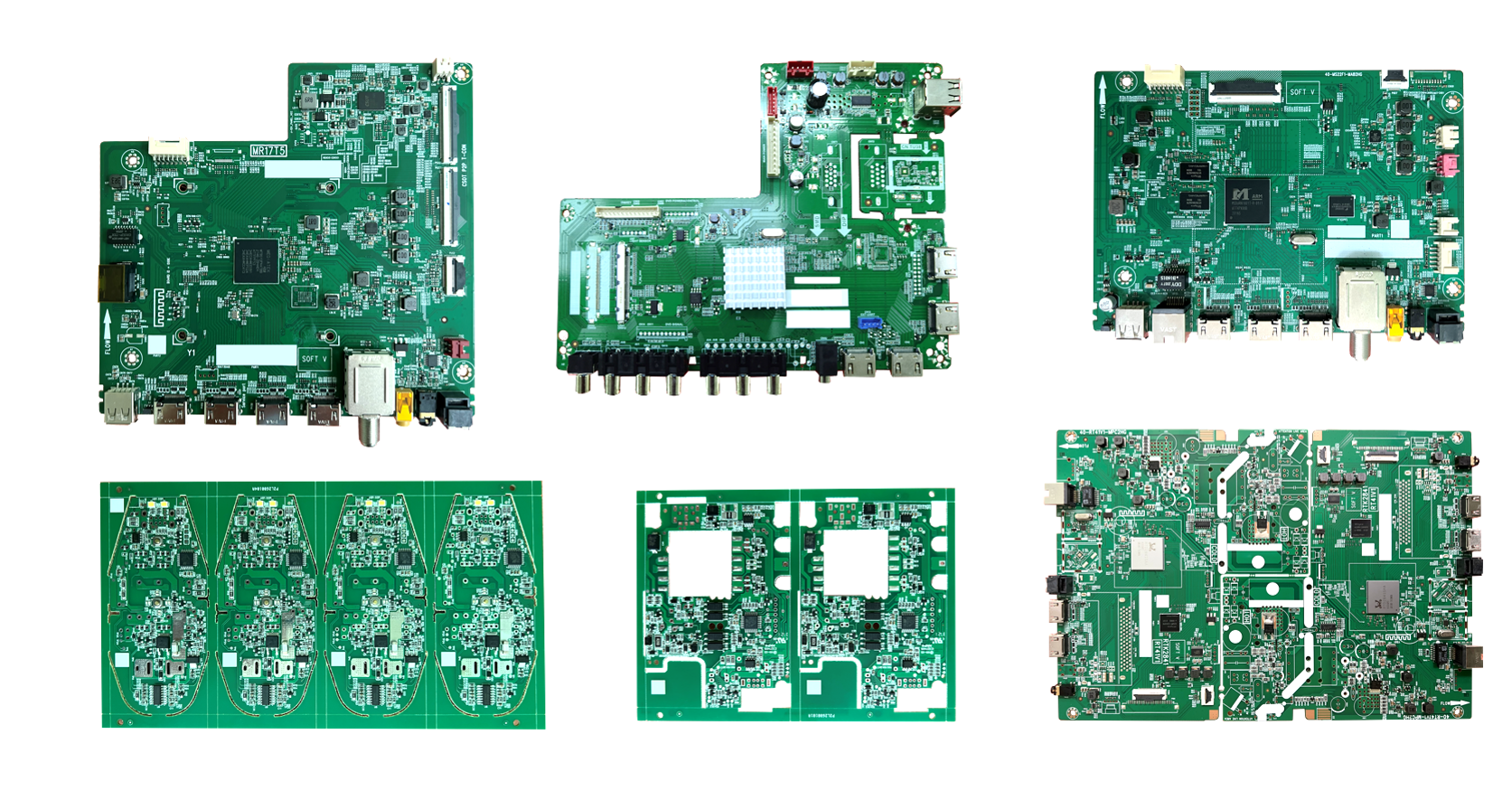

Basic product images of each production

Amtecor accepts large-scale electronic circuit board manufacturing:

To receive a quote, please send the Gerber file and BOM to the mailbox tonhuynh@amtecor.com